Table of Contents

بررسی اهمیت فلزیاب های صنعتی در حفظ کیفیت محصول

علاوه بر این، استفاده از فلزیاب های صنعتی به حفظ اعتبار برندها نیز کمک می کند. در بازار رقابتی امروز، کیفیت محصولات یک عامل کلیدی است که بر انتخاب مصرف کننده تأثیر می گذارد. هر گونه مصالحه در کیفیت محصول می تواند منجر به از دست دادن اعتماد مصرف کننده شود و می تواند تأثیر مخربی بر شهرت یک برند داشته باشد. فلزیابهای صنعتی با اطمینان از عاری بودن محصولات از آلایندههای فلزی، به حفظ کیفیت محصولات کمک میکنند و در نتیجه به حفظ و ارتقای شهرت برند کمک میکنند. آنها به شناسایی و حذف آلاینده های فلزی از محصولات کمک می کنند و در نتیجه از سلامت مصرف کننده محافظت می کنند و یکپارچگی محصولات را حفظ می کنند. علاوه بر این، آنها همچنین با اطمینان از اینکه محصولات مطابق با استانداردهای با کیفیتی هستند که مصرف کنندگان انتظار دارند، به محافظت از شهرت برندها کمک می کنند. بنابراین نمی توان اهمیت فلزیاب های صنعتی را در حفظ کیفیت محصول نادیده گرفت. آنها ابزاری ضروری در فرآیند تولید هستند و به طور قابل توجهی به ایمنی، کیفیت و شهرت محصولات کمک می کنند.

نقش فلزیاب های صنعتی در افزایش و تضمین کیفیت محصولات

The Role of Industrial Metal Detectors in Enhancing and Ensuring the Quality of Products

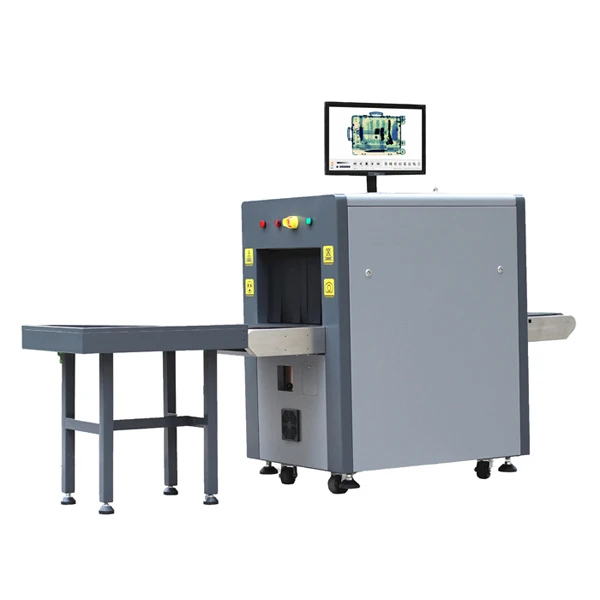

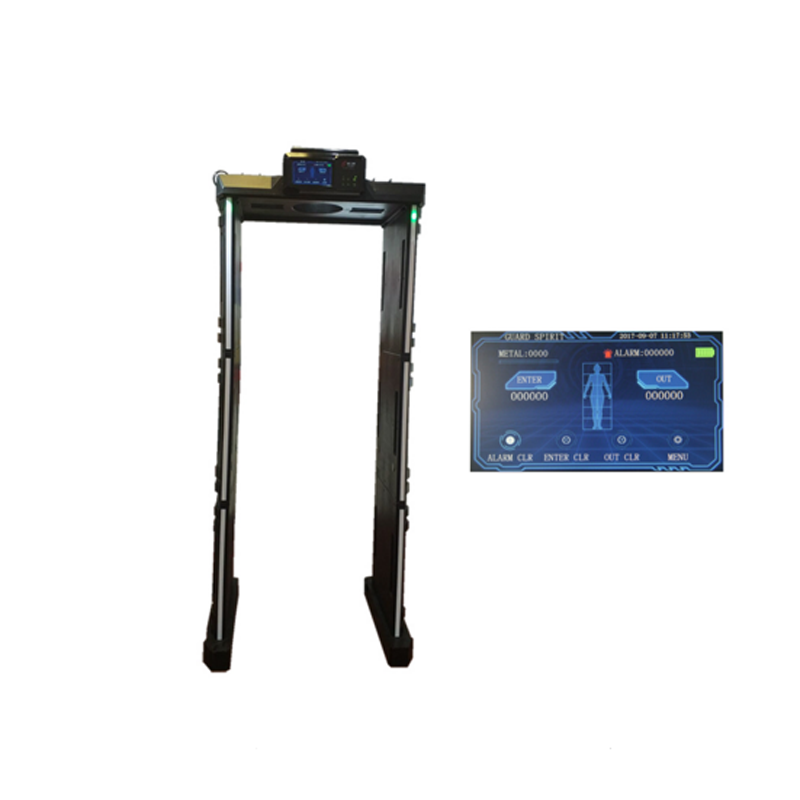

Industrial metal detectors play a pivotal role in enhancing and ensuring the quality of products across a wide range of industries. These sophisticated devices are designed to detect the presence of metal contaminants that may inadvertently find their way into products during the manufacturing process. The use of industrial metal detectors is not only a matter of maintaining product quality, but also of ensuring consumer safety and protecting brand reputation.

The primary function of industrial metal detectors is to identify and eliminate metallic contaminants from raw materials or finished products. These contaminants can originate from a variety of sources, such as machinery wear, raw material contamination, or human error. Regardless of the source, the presence of metal contaminants can significantly compromise the quality of the product, leading to potential harm to the consumer and damage to the company’s reputation.

Industrial metal detectors work by generating a magnetic field. When a metal object passes through this field, it disrupts the balance, triggering an alarm. The product can then be removed from the production line for further inspection, ensuring that no contaminated items reach the consumer. This process is crucial in industries such as food processing, pharmaceuticals, textiles, and plastics, where the presence of metal contaminants can have serious consequences.

In the food industry, for example, metal contaminants can pose a significant health risk to consumers. They can cause physical harm if ingested, and can also lead to product recalls, legal action, and damage to the brand’s reputation. By using industrial metal detectors, food manufacturers can ensure that their products are free from harmful metal contaminants, thereby safeguarding consumer health and maintaining the integrity of their brand.

In the pharmaceutical industry, the presence of metal contaminants can compromise the efficacy of medications and potentially pose a health risk to patients. Industrial metal detectors are therefore used to ensure that medications are free from metallic contaminants, thereby ensuring their safety and effectiveness.

In addition to enhancing product quality and safety, industrial metal detectors also contribute to operational efficiency. By identifying and eliminating metal contaminants early in the production process, these devices help to prevent costly equipment damage and downtime. They also help to reduce waste by ensuring that contaminated products do not proceed further down the production line.

Moreover, the use of industrial metal detectors can help companies comply with regulatory standards. Many industries are subject to strict regulations regarding product safety and quality, and failure to comply with these standards can result in hefty fines and other penalties. By using industrial metal detectors to ensure that their products are free from metal contaminants, companies can demonstrate their commitment to product safety and quality, and can avoid the potential legal and financial repercussions of non-compliance.

In conclusion, industrial metal detectors play a crucial role in enhancing and ensuring the quality of products across a wide range of industries. By detecting and eliminating metal contaminants, these devices help to ensure product safety, protect brand reputation, increase operational efficiency, and facilitate regulatory compliance. As such, they are an indispensable tool in the quest for product quality and consumer safety.