Understanding the Basics of Industrial Metal Detectors

Industrial metal detectors are essential tools used in various industries to ensure product quality, safety, and compliance with regulations. These devices are designed to detect the presence of metal contaminants in products or materials during the manufacturing process. Understanding how industrial metal detectors work and their different types can help businesses make informed decisions when selecting the right equipment for their specific needs.

Metal detectors operate on the principle of electromagnetic induction, which involves generating an electromagnetic field and detecting changes in that field caused by the presence of metal objects. When a metal object passes through the electromagnetic field, it disrupts the field, triggering an alarm or signal to alert operators of the presence of metal contaminants. This technology is highly effective in detecting a wide range of metal types, including ferrous, non-ferrous, and stainless steel.

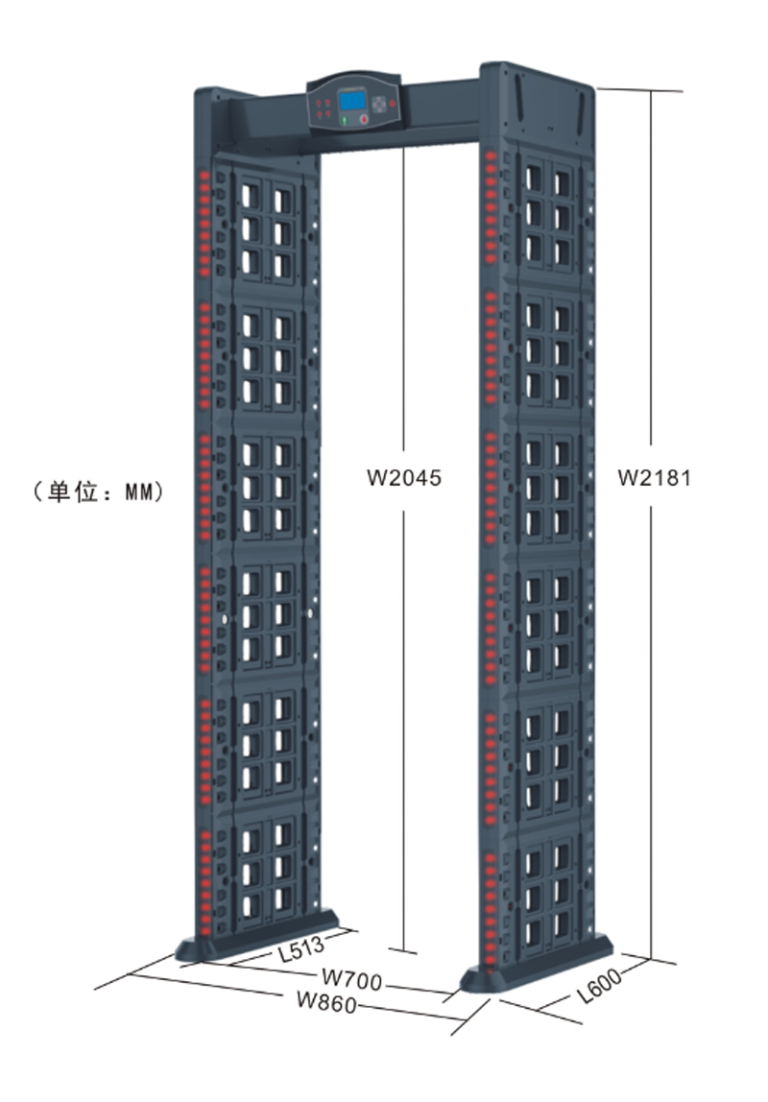

There are several types of industrial metal detectors available on the market, each designed for specific applications and environments. The most common types include conveyor belt metal detectors, pipeline metal detectors, gravity feed metal detectors, and handheld metal detectors. Conveyor belt metal detectors are typically used in food processing and packaging industries to inspect products as they move along a conveyor belt. Pipeline metal detectors are used in the pharmaceutical and chemical industries to inspect liquids and powders flowing through pipelines. Gravity feed metal detectors are used in bulk material handling industries to inspect products as they fall through a gravity feed system. Handheld metal detectors are used for manual inspection of products or materials in various industries.

When selecting an industrial metal detector, businesses should consider factors such as the type of product being inspected, the size and shape of the metal contaminants, the sensitivity and detection capabilities of the device, and the environmental conditions in which the detector will be used. It is essential to choose a metal detector that can effectively detect metal contaminants without generating false alarms or compromising production efficiency.

Regular maintenance and calibration of industrial metal detectors are crucial to ensure optimal performance and accuracy. Calibration involves adjusting the sensitivity and settings of the metal detector to detect metal contaminants of a specific size and type. Routine maintenance tasks include cleaning the detector, inspecting for wear and tear, and replacing worn components to prevent malfunctions and ensure reliable operation.

In conclusion, industrial metal detectors play a vital role in ensuring product quality, safety, and compliance in various industries. By understanding how these devices work and their different types, businesses can make informed decisions when selecting the right equipment for their specific needs. Regular maintenance and calibration of metal detectors are essential to ensure optimal performance and accuracy. With proper care and attention, industrial metal detectors can help businesses maintain high standards of quality and safety in their operations.